UPDATED AUGUST 3, 2025

In Lesson #5, we recapped the quality of a leather hide: the source, split and tannage. Once it's been tanned, it's ready to be finished with surface treatments: colors and coatings.

In this post, we'll explain the various kinds of finishes, which can be done at the tannery or in the craft workshop. It can comprise any (or none): waxes, dyes, veneers, pattern stamping.

Some finishes are designed to bring out the leather's glory, or protect it from the elements. Other finishes are designed to hide the leather, or make it look like something it's not.

Leather Learning Series

This post is part of our "Leather 101" educational series. We're sharing everything we know about our favorite material!

Jump to Section

Once a cowhide is preserved for long life through tanning, the tannery can choose to apply any number of finishing treatments to it to change, enhance, or obscure its look, feel, or durability --- or not, because natural leathers can be finished in the workshop.

The finishing process is where much of the confusion between leathers come from. Many of the treatments are done to obscure the actual quality of the leather. Some finishing treatments provide useful shortcuts for those in the workshops and factories making products out of leather.

Finishing Full-Grain Vegetable-Tanned Cowhide ("Tooling Leather")

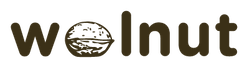

Tooling leather (full grain, vegetable-tanned) is the highest quality and most natural leather available. This is the kind of leather we use in the Walnut Studiolo workshop. It comes to our workshop with no finishes as-is.

Because the surface is so beautiful and natural, it's common to use oil dyes instead of paints on the surface, which is analogous to staining wood instead of painting so that the wood grain and warm colors shine through. We can also be flexible in how we use each hide, cutting and dyeing each piece to-order.

Many leather craftspeople use this kind of leather for carving in artwork using a wide variety of stamping tools, which is why it's called tooling leather. Here are some examples of tooled leather, with and without colored dyes and paints:

As shown in the Hermann Oaks factory tour in St. Louis Missouri, this leather is nearly a blank canvas. The natural color varies from light tan to almost light pink. (This is why it can't become white unless it were somehow bleached.)

Although the surface has been lightly sanded, the natural textures still show up in the grain: the creases, wrinkles, insect bites, and stretch marks of the cow's life.

If color is needed, this kind of leather gets painted and dyed in the workshop. In some workshops, that can means airbrushing, sometimes acrylic paints, but in our workshop that means rubbing in oil dye by hand. Very few workshops do this kind of work by hand anymore.

Many believe this is the highest form leather can take - a high quality leather rubbed to a natural, lustrous shine. The leather has a smooth front side and a napped backside, which soaks up dye. Because the leather comes in its natural state, the edges need to be specially treated as well as the surface to give the leather a homogenous look. So, for example, if the surface is dyed black, then the sides/edges would also need to be dyed black.

Once the dye has dried, we seal it in with a clear natural coat to "set" the dye. None of these finishes involve plastics or brushes, but are rubbed in by hand with rags and have short, simple ingredient lists.

Leathers Finished at the Tannery

Full-Grain Vegetable-Tanned "Bridle Leather" (Harness Leather)

Bridle leather and super-thick skirt leather is the same thing as full grain vegetable-tanned cowhide, but the tannery takes it a step further and gives the leather a strong, industrial treatment of dyes, oils, and waxes.

Designed for horse tack (bridles, harnesses, reins, etc), this leather is as tough as it gets and perfect for any product that is going to get muddy or mucky or salty.

Photo credit: Erin Berzel for DK Publishing

Bridle leather comes to the craftsman already dyed. Because bridle leather is infused with copious waxes and oils to stand up to the elements, the tannery also dyes it in-house. Waxes prevent the penetration of dye. The dye is usually applied in large batches in a drum tumbler. This leather arrives ready to cut and assemble into products.

This treatment enhances the leather's weatherproofness and durability in a way that can't be done by a craftsman in a workshop, but it also means that the color is a flat, homogeneous, matte color. It's missing the glow and surface character of hand-rubbed oil dye, and it's only available in a limited number of colors.

Another benefit to bridle leather is both the grain side and flesh side are treated with dyes, oils, and waxes, so it looks the same on both sides. This is a good choice for projects that need to look finished on both sides, and that will provide a smooth, comfortable feel for a horse or other pack animal.

Note: Another term commonly used, "English Bridle Leather," refers to the appellation, meaning bridle leather that is tanned in England.

Top Grain Vegetable-Tanned and Mixed-Tanned Leathers

Because top grain leather has the surface split off, there is a huge variety of looks and finishes put back on.

Mixed-tannage leathers are those that have gone through both tanning processes: first garment tanning, then vegetable-tanning. They are often sold as "vegetable-tanned" leather without further detail, because of the premium pricing possible for vegetable-tanned leathers.

Among these kinds of leather, color treatment is one of the first considerations:

Among grain leathers there are three general categories: aniline, semi-aniline, and protected. Aniline leathers are processed using soluble dyes to maintain their natural markings and texture, and do not have a surface pigment or coating. This makes them the most natural-looking leathers, but also more susceptible to scratching, fading and staining. Semi-aniline leathers (like most bridle leathers) are treated with pigments and thus conceal more blemishes and have a more uniform coating, as well as staying more protected. Protected leathers have a non-leather coating sprayed or attached to the leather as a protectant. - Best Leather

Many of the color and printing treatments applied to top grain vegetable-tanned leather have the effect of mimicking the look of full grain vegetable-tanned leather, or another leather entirely, such as with the imprint of a different animal's hide markings, like faux crocodile.

Mineral-Tanned Leather Finishes (Chrome-Tanned, Garment Leather)

Garment leather is one of the most commonly-available mineral-tanned leathers. It is a top grain leather with a sanded, homogeneous surface and usually finished in the tannery with dyes, sometimes with textures, and with any of a number of polymers and coatings to enhance its durability.

The dye penetrates through the entire thickness of the leather, but it is not colorfast. Although colors stay intact in wet conditions, they can fade in the sun. This is the type of leather usually used in shoes, purses, and clothing. It performs well in typically indoor applications.

Manufacturers can apply all kinds of treatments to leather to make it look exactly how they want. For example, nubuck is a top grain leather with a sanded finishing that makes it soft like suede. Deerskin, pigskin, and sheepskin, and goatskin are usually mineral-tanned and dyed and finished in the tanneries as well.

Lesson #6 at the Walnut Workshop

Bicycle Leather Mud Flaps

We only use bridle leather for a few products in our studio, like the Bicycle Mud Flaps.

Bridle leather has been infused with extra waxes at the tannery. It provides maximum protection and durability in wet and mucky environments, which is exactly what mud flaps need.

The color isn't an exact match to our other hand-dyed bicycle products, but we think it's a worthy compromise for durability in the roughest possible road conditions.

Next Lesson

Now that our full grain vegetable-tanned cowhide is in the workshop and finished, it's ready to be turned into products!

In Lesson #7, we'll discuss quality leather gets turned into quality products, by selecting the right kind of leather for the right job.

Leather Learning Series

This post is part of our "Leather 101" educational series. We're sharing everything we know about our favorite material!

- Lesson 1: Leather Basics

- Lesson 2: Leather Sources

- Lesson 3: Leather Processing

- Lesson 4: Leather Tanning

- Lesson 5: Recap: The "Best" Leather

- Lesson 6: Leather Finishes

- NEXT --> Lesson 7: Leather Product Quality

- Lesson 8: Recap: The "Most Sustainable" Leather

- Lesson 9: Vintage Leather in the Store

- Lesson 10: Leather Rescue and Rehabilitation

- Lesson 11: Leather Care and Crafting

Get the full series delivered to your inbox in one email per day for 11 days:

Sign up for the email series >>>

Leave a comment (all fields required)