UPDATED JULY 29, 2025

In Leather Learning Lessons 1-4, we discussed leather production processes, which show the wide variety of leather types and tannages available. The source, processing production, tanning method and finishes can all have an impact on final quality.

In this post, we'll review Lessons 1-4 by putting everything we've learned together.

Leather Learning Series

This post is part of our "Leather 101" educational series. We're sharing everything we know about our favorite material!

Jump to Section

Leather Source

In Lesson #2, we covered leather sourcing. Most of the leather tanned and used globally is a byproduct of the meat industry: beef, pig, and even kangaroo. There are also exotic leathers and alternatives made from plastics and plants. 67% of leather tanned globally is cowhide.

Tough cowhide is the traditional and most quality choice for thickness and durability.

Leather Split

In Lesson #3, we covered leather splitting, which is how leather is processed based on its condition. Many poor quality hides are sanded, split, or even reconstituted from adhesives and dust to make top grain, suede, genuine, and bonded leathers.

Only 10-15% of cowhides are good enough to be kept in their natural, un-sanded state, which is called full grain leather.

Leather Tannage

In Lesson #4, we covered leather tannages, which is how leather is preserved with tannins or chemicals for perpetual use.

Less than 10% of full grain leather hides are tanned using the more traditional "veg tan" method, which uses natural plant tannins. Vegetable-tanning is more labor-intensive and takes longer, making it more expensive.

Of those, an even smaller fraction are tanned in countries with robust environmental and labor laws, like the United States, South Korea, and Italy. Although the US is a large beef producer, American tanneries are in decline: only 110 remained in 1995, down from 386 in 1982.

Putting It Together: The Best Leather Infographic

Recap from Lesson #1

LEATHER TYPE = source + split + tannage + finish

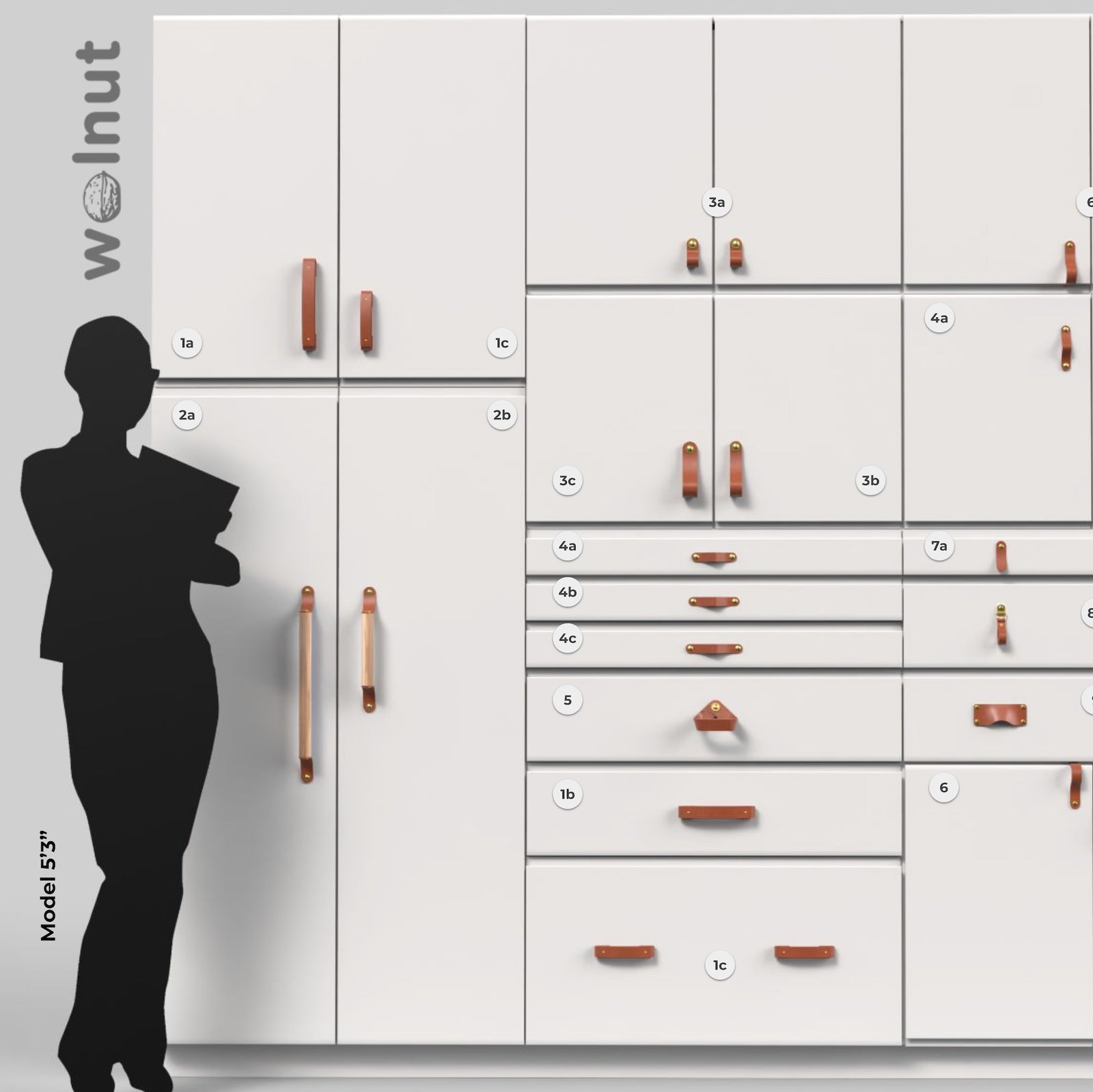

Here at Walnut Studiolo, we believe we use the "best" and most quality leather available:

- USDA beef cattle sourced in America

- Full grain (unsanded)

- Vegetable-tanned in America

Lesson #5 at the Walnut Workshop

Original Travel Cribbage Board

We utilize all the unique qualities of full grain cowhide to the advantage of cribbage players worldwide: thinness with flex and strength.

The luster of full grain leather and the crisp deboss surface of veg-tan leather makes it perfect for monogramming special messages.

Shop Original Travel Cribbage Board >>>

Next Lesson

Together, these 3 choices determine much of the quality of the leather itself: source, split, and tannage.

In Lesson #6, we'll discuss leather finishes, and how companies and crafts people turn quality hides into quality products.

In other words, how you can tell if the right leather being used for the right product?

Leather Learning Series

This post is part of our "Leather 101" educational series. We're sharing everything we know about our favorite material!

- Lesson 1: Leather Basics

- Lesson 2: Leather Sources

- Lesson 3: Leather Processing

- Lesson 4: Leather Tanning

- Lesson 5: Recap: The "Best" Leather

- NEXT --> Lesson 6: Leather Finishes

- Lesson 7: Leather Variability and Product Quality

- Lesson 8: Recap: The "Most Sustainable" Leather

- Lesson 9: Vintage Leather in the Store

- Lesson 10: Leather Rescue and Rehabilitation

- Lesson 11: Leather Care and Crafting

Get the full series delivered to your inbox in one email per day for 11 days:

Sign up for the email series >>>

walnutstudiolo

July 11, 2023

Thank you for the kind words, Bruce! We are constantly delighted by our customers – you are great to work with too! Happy New Year! -Valerie, Walnut Studiolo