UPDATED JULY 22, 2025

In Lesson #6, we talked about finishes, coatings, and colorings. Today we discuss another aspect of leathercrafting that happens during production: the variability of each hide, by shape, thickness, and stretchiness.

In this post, we'll explain these variables, and what it means you should look for when deciding whether a product is quality. In other words, is the product overly expensive or overly economizing? Is it using the right leather for the right purpose to ensure a long and useful life? Plus - why maker-made matters.

Leather Learning Series

This post is part of our "Leather 101" educational series. We're sharing everything we know about our favorite material!

Jump to Section

Real Leather Hides Have Natural Variations

The shape of real leather hides is irregular (which is why it's not used for upholstery, as discussed in a previous lesson!). It's sold by the square foot but comes in wonky, curvy shapes.

Plus, each hide varies in both fiber structure and thickness, with some areas stretchy and some firm, some thick and some thin.

Thus, the craftsperson is challenged to use every square inch (millimeter) of leather they can. They already paid for it, so they want to produce as little waste as possible. This not only keeps costs down, but it honors the animal and the hide. They have to balance this thrift while still having the restraint, foresight, and knowledge to save the right area of the hide for the right product.

Leather Crafters Use Variations to Their Advantage

Leather is an expensive material and leathercrafting is time-intensive work, so makers want to make sure they select the most cost-effective leather for the job, and time is money. But beyond basic leather choice and color, there are a lot of other decisions to make on which leather to use for which products.

There are a few important questions to ask when deciding which is the right leather for a given product or use:

- Does it need to age well or is it planned to be disposable?

- Will it use the hide shape efficiently or will there be a lot of waste?

- Does it need to stretch, or does it need to keep firm?

- Will it be used indoors or outdoors?

- Will it be in wet/mucky conditions or in dry/clean conditions?

- Should it drape with gravity or does it need to hold up on its own?

- Does it need to support the weight of something else? Where are the pressure points?

- Does it need to have a particular color or look?

- Will the edges be showing?

- Does it need to be sewn?

Leather Shape

Hides come in irregular shapes and are priced by the square foot, so it's the job of a maker or craftsperson to create regular shapes out of them for products with as little waste as possible. If not done carefully, this can create a lot of waste, which increases costs.

Leather Fiber Structure

Across each hide are different areas that correspond to different body parts. For example, bellies have lots of stretch, spongy fibers, and the most variable thicknesses. Butts have the tightest fiber structure, but are the most expensive.

Depending on the product and its use, it might make more sense to use the less expensive stretchy area of a hide, or not.

Leather Weight / Thickness

Full grain vegetable-tanned cowhide comes in a variety of thicknesses. They are the same quality of leather, but different thicknesses work for different purposes.

Thin leather can be fabric-like: strong but flexible for wrapping and coating. Thick leather can be wood-like: sturdy and structural.

More thickness = greater rigidity, but for example a folding cribbage board doesn't need extra rigidity or it wouldn't fold well. On the flip side, a barrel-shaped saddle bag needs rigidity to hold itself proud and to maximize its volume for the protection of its contents.

Leather thickness is measured in a unique system called "ounces" -- but it relates thickness rather than weight.

Hides come usually as an average of two weights because the actual hide may vary thickness across its expanse. Such as: 8/9 leather that would vary from 1/8" to 9/64" or 2/3 leather that would vary from 1/32" to 3/64".

| "Ounce" | Thickness (in.) | Thickness (mm) |

| 1 | 1/64" | 0.4mm |

| 2 | 1/32" | 0.8mm |

| 3 | 3/64" | 1.2mm |

| 4 | 1/16" | 1.6mm |

| 5 | 5/64" | 2.0mm |

| 6 | 3/32" | 2.4mm |

| 7 | 7/64" | 2.8mm |

| 8 | 1/8" | 3.2mm |

| 9 | 9/64" | 3.6mm |

| 10 | 5/32" | 4.0mm |

| 11 | 11/64" | 4.4mm |

| 12 | 3/16" | 4.8mm |

Leather Durability

Craftspeople also have to match the tannage to the use, economizing where it makes sense:

- Vegetable-tanned leather does fine in the outdoors so long as it's conditioned from time to time.

- Bridle leather is infused with extra waxes to stand up proud against the rigors of sun and rain, but is overly expensive for indoor use.

- Garment leather fades and deteriorates in the sun or wet or mucky conditions, but it's the least expensive choice with the most options for color and appearance for draping or indoor uses.

- Bonded leather is fabricated into rolls and kept flexible with glues and chemicals, making it a good choice for large expanses like furniture and car upholstery.

Photo credit: Reddit

Craftsmanship Details: Why Maker-made Matters

This is where true craftsmanship begins. Manufacturers and craftspeople alike have to make tough choices to keep costs down while providing the best product they can. Often in manufacturing, the cost outweighs the quality.

We consider it to be the job of makers and craftspeople to be the few, the specialists, who are willing to put in the extra time and care to make a quality product, even if it costs more. Somebody's got to do it right!

Some examples of the choices and details that are made with every product:

- Will the edges be showing? For vegetable-tanned leather, the edges may need to be treated so they are the same color as the surface if they are going to be visible - or perhaps the craftsperson may decide to cut this corner to keep costs down. Is it worthwhile to bevel the edges for a finer grip, or wax the edges for wet conditions?

- If it needs to be sewn, is it too thick to get through a standard sewing machine or a tough denim/leather machine? Will it need stronger hand-stitching?

- Does it need to be white, or neon purple? The color may not be achievable on vegetable-tanned leather, but it may be readily available in garment leather.

Photo credit: YouTube

Lesson #7 at the Walnut Workshop

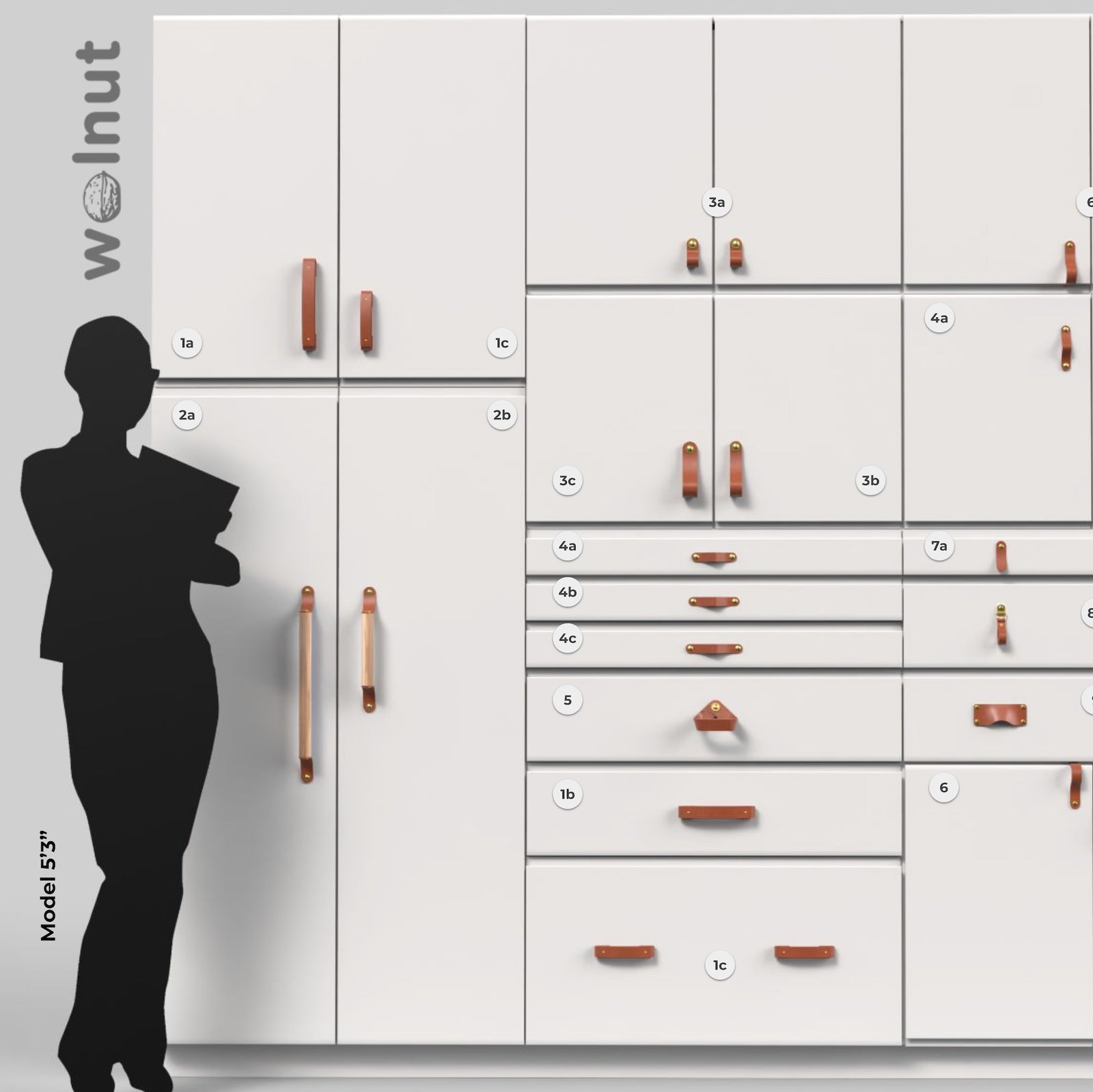

Leather Drawer Pulls

Across our Leather Drawer Pulls Collection, we use 4 different thicknesses of high quality full grain veg-tan leather, matching the right thickness for the right design.

For example, some need thick structural integrity to fight gravity and stand off the cabinet door like the Sellwood, while others need the stretch and flex to form a tight loop, like the Burnside.

Browse the Leather Handles Collection >>>

Next Lesson

We are proud to be the makers and leather craftspeople making our own designs and our design decisions. Not only does this translate to choosing what we believe to be the right leathers and the right quality we would want in products ourselves, but also the right environmental values.

In Lesson #8, we'll recap all we've learned so far with a discussion on what "sustainable" leather means, and how products can be chosen in accordance with cherished values.

Leather Learning Series

This post is part of our "Leather 101" educational series. We're sharing everything we know about our favorite material!

- Lesson 1: Leather Basics

- Lesson 2: Leather Sources

- Lesson 3: Leather Processing

- Lesson 4: Leather Tanning

- Lesson 5: Recap: The "Best" Leather

- Lesson 6: Leather Finishes

- Lesson 7: Leather Variability and Product Quality

- NEXT -->Lesson 8: Recap: The "Most Sustainable" Leather

- Lesson 9: Vintage Leather in the Store

- Lesson 10: Leather Rescue and Rehabilitation

- Lesson 11: Leather Care and Crafting

Get the full series delivered to your inbox in one email per day for 11 days:

Sign up for the email series >>>

Leave a comment (all fields required)